small is great!

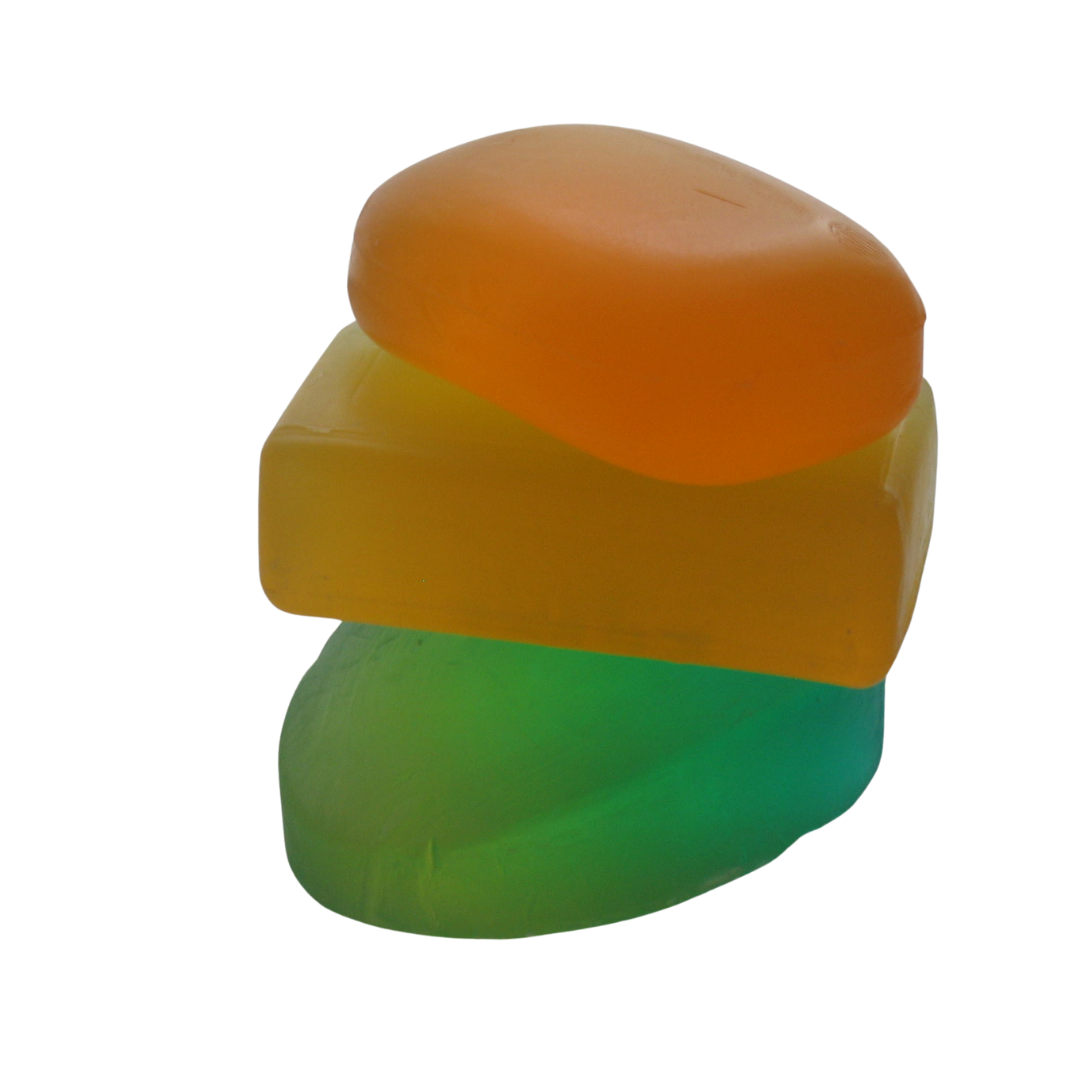

Artisan Line: Machines for the Production of Handcrafted Soap

If you’re a soap producer looking for a fully automated, industrial-level solution tailored to your specific needs, Saponcino’s Artisan Line is exactly what you’re looking for.

The soap production machines of the Artisan Line are designed for ease of use and simple maintenance, with a production capacity of up to 500 kg/h. Thanks to the modular design, you can customize the line to match your business needs. The Artisan Line also allows the production of soap bars in any shape and size, giving you full creative freedom.

If you are looking for a soap production line that combines innovation, efficiency, and a lower investment, the Artisan Line is the perfect solution for your business.

Machines in the Artisan Line

The Saponcino Artisan Line includes a complete range of machines designed to optimize every phase of production.

Mixers

Roll Mills

Refiners

Duplex

Cutters

Stampers

Mixers

Mixers are essential machines for achieving a homogeneous soap dough, a key factor in determining the quality and consistency of the final product.

The AM-100T is an open sigma mixer with tilting discharge, operable manually or automatically. It’s highly versatile and easy to use.

The AM-100B features a bottom discharge valve activated by a pneumatic system, making the unloading process even more efficient—ideal for increasing speed and precision in transferring mixed materials.

Roll Mills

Roll mills are essential tools for flattening soap into thin sheets, ready for further processing. These machines ensure a uniform consistency and help maintain the highest product quality standards.

The M-200 is a three-roll mill, 700 mm long, equipped with two rolling systems to ensure continuous, uniform production. Thanks to the triple-roll configuration, the milling process is smooth and the resulting semi-finished product has a consistently perfect texture.

Refiners

Refiners are designed to enhance the quality of the soap by removing impurities and improving its texture.

The SRs-200 is a Simplex (single-stage) refining extruder with a 200 mm diameter screw and a 3:1 compression ratio. It’s ideal for small to medium productions requiring quick and precise refining.

The DRs-200 is a Duplex (double-stage) refining extruder that guarantees deeper refining and even purer soap. With the same 200 mm screw, the Duplex model is suited for larger productions and superior quality outcomes.

Duplex Vacuum Plodder

Duplex Vacuum Plodder are designed to further improve soap quality using a unique system that reduces moisture. They operate similarly to refiners: a long screw with progressively decreasing pitch compresses and pushes the product. Unlike refiners, where the process ends with a perforated plate and blade for pellet extrusion, the Vacuum Duplex Extruder uses a conical head to extrude a homogeneous soap bar.

The DVs-200 is a Duplex Vacuum Plodder with one screw per stage, each 200 mm in diameter. The 3:1 compression ratio and vacuum efficiency enable advanced refining that significantly enhances soap consistency and quality.

Cutters

Cutters are used to divide extruded soap into precise, uniform pieces. These machines are crucial for optimizing production, reducing waste, and achieving bars with perfect shape and size.

The MBC-P is an automatic single-blade cutter that performs “in-flight” cuts on extruded soap blocks. A pneumatic piston ensures fast, precise cuts, reducing production time and enhancing cut quality.

The MBC-1 is a next-generation automatic soap cutter designed for accurate, reliable, and uniform cuts using servo motor-powered single blades. This high-precision system ensures consistent operation even at high production speeds.

The MBC-1 can be configured with vertical and/or horizontal engraving rolls to fully customize the soap bar before cutting. The perfect synchronization between rolls and cutting system ensures that the stamp remains exactly centered on the bar, regardless of the cutting length.

Stampers

Stampers are machines used to create soap bars with intricate shapes and details—ideal for artisans who want to produce unique, customized soaps.

The MFS is a stamper specifically designed for artisan soap makers who require detailed shapes and impeccable quality. With precision and robust construction, it’s ideal for creating a wide variety of soap forms that meet high standards of quality and personalization.

4 Reasons Why the Artisan Line Is Right for You

Extremely easy to use and safe to operate

Minimal maintenance requirements

Ability to produce various types of solid soap

Customizable production line thanks to modular design